ALERT

ALERT **Important for iLab Users**

The Help link in iLab opens an email to contact Support. To submit or track requests, visit: Submit and Track Support Requests

About Us

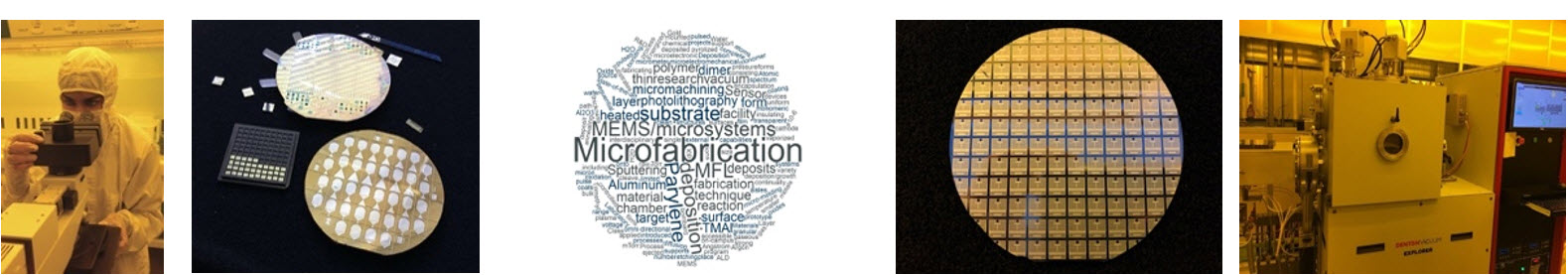

The Microfabrication Laboratory (MFL) is part of the Case School of Engineering, and is professionally staffed and managed. We serve investigators from a number of departments within the University as well as external organizations looking for prototype fabrication and R&D services. The MFL is a 5500 sq. ft. class 100 clean room facility that facilitates the fabrication of microelectromechanical systems (MEMS) and other devices. Fabrication equipment used in the measurement, deposition, patterning, etching, and heat treatment of microelectronic devices is available.

Services

Equipment and Technology Photolithography

Metal Deposition

Thin Films Deposition

Etch

Dielectric/Insulators

| Hours | Location |

|

Monday - Friday 8am - 4pm

|

2104 Adelbert Road Bingham Building, Room 320, Case Western Reserve University Cleveland, OH 44106 |

| Name | Role | Phone | Location | |

|---|---|---|---|---|

| Nichole Hoven |

Core Manager

|

216-368-0264

|

nichole.hoven@case.edu

|

CWRU, Bingham 320

|

| Chris Zorman, PhD |

Core Director

|

216.368.6117

|

christian.zorman@case.edu

|

CWRU, Nord 500

|